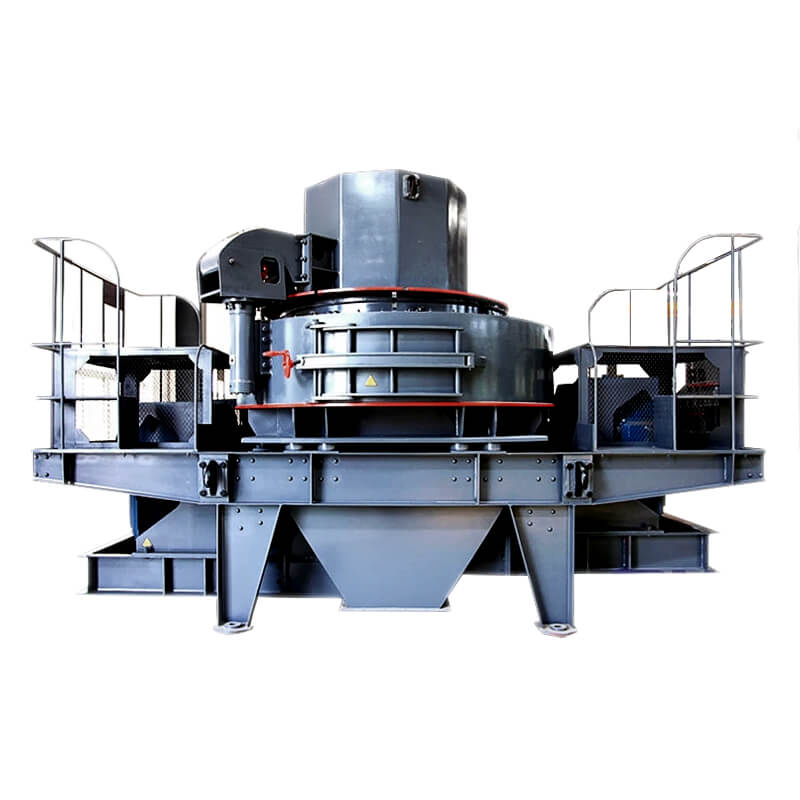

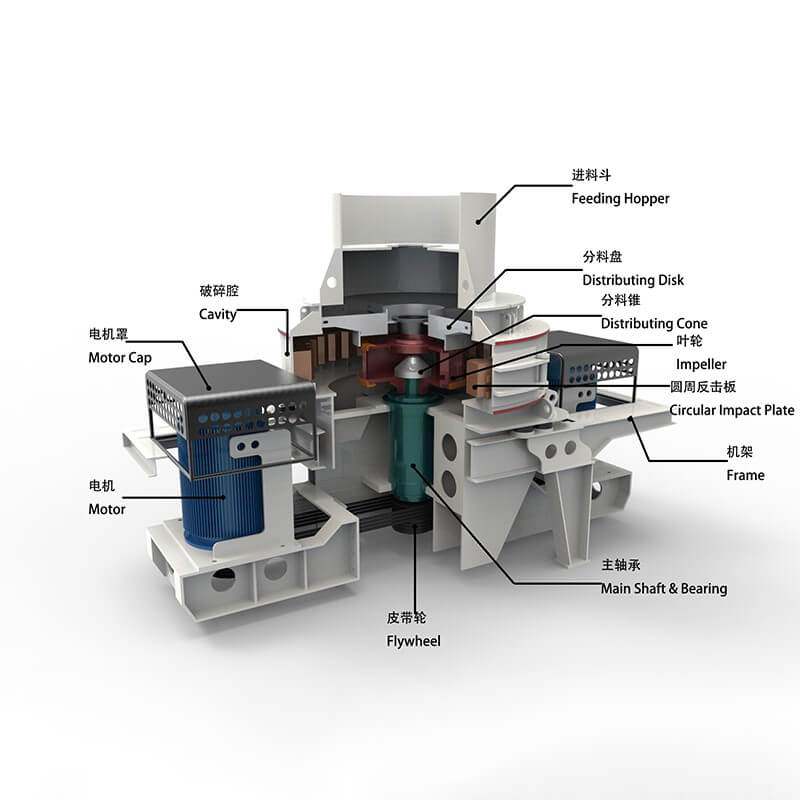

Impact crusher, commonly known as sand making machine, is an internationally advanced high-energy low-consumption impact crusher. Its performance plays an irreplaceable role in various ore fine crushing equipment. It is currently the most effective, practical and reliable stone crushing machine.

The mobile impact crushing plant, also known as the tracked impact crusher or recycling impactor, is recognizable mainly due to the fact that these crushers are mounted on a tracked undercarriage. Our mobile impact crusher belongs to the better performance of the crushing station series equipment. The crushing system is equipped with a high-performance impact crusher, which has large crushing capacity and high production efficiency. It is one of the equipment often purchased in large-scale beneficiation production lines. The impact mobile crushing sand making station is not only equipped with a better crushing system, but also equipped with common mining equipment such as vibrating feeders, linear vibrating screens, belt conveyors, etc., forming a production line for production operations. The production efficiency is very high. Customers bring greater economic benefits, which is an ideal choice for users of large mines.

Adapting to a changing industry Tracked impact crushing plants have evolved greatly over the last several decades as their designs have been continuously updated and as the crushing market has changed. Major trends include the introduction of electric power and hybrid systems as opposed to diesel-hydraulic drive systems, and decreases in size, weight, fuel consumption, cost-per-ton, and sound and dust generation. Today’s impact crushers are also available compliant to Tier 4 Final emissions standards, and can be equipped with or without a built-in screen as well as many options specifically geared towards creating recycled materials. They are safer, more mobile, easier to maintain and operate, and are available with sophisticated machine automation and monitoring.

Over the last 10 years we have improved our control panel systems to provide operators with more knowledge and information about what is going on inside their machines at all times. The units are also easier and faster to set up.

“The impact crusher’s ability to handle steel-reinforced concrete, along with custom options, such as plastics and wood-waste removal systems, washing systems and more, has enabled recyclers to create much higher quality end products, and crush and process materials previously deemed only waste, or too difficult to process.” “The impactor has developed over the past 20 years to become one of the most important tools used in the recycling of C&D waste,” adds Michael Brookshaw, global distribution manager for Keestrack. “The reason is the quality of the material and very cubical shape produced. The impact crusher is a first- and second-stage crusher in one unit, so you can crush a 600-mm product down to a final product for resale as recycling aggregate.

Our machines are excellent in recycling asphalt, as we can slow down the rotor speed to crush the asphalt, but not the aggregate inside the asphalt, so the material can be reused in asphalt mixing plants, a huge savings on cost.